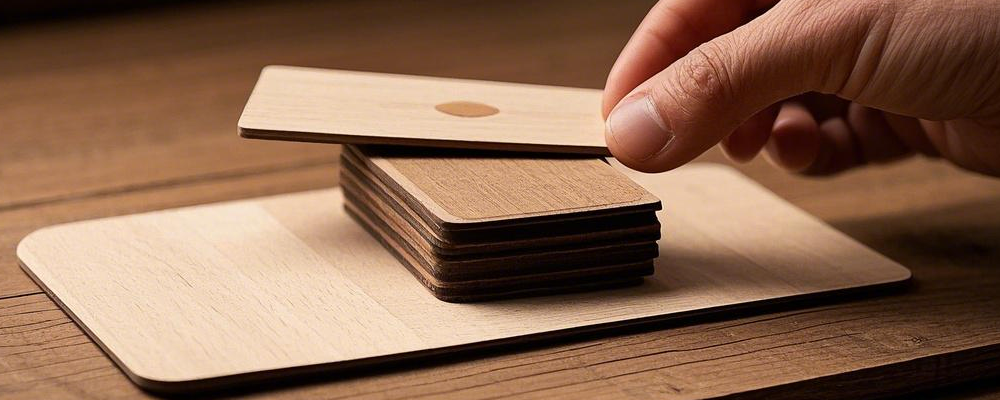

Wooden cards are made through a detailed process that involves cutting, shaping, and finishing thin slices of wood. These cards are often used for business cards, gift cards, or playing cards, and they combine natural aesthetics with durability. Here’s a step-by-step breakdown of how wooden cards are typically made:

1. Material Selection

-

High-quality wood is chosen based on the desired appearance and functionality. Common types include:

-

Maple: Light-colored and smooth.

-

Walnut: Dark and rich in texture.

-

Cherry: Warm reddish tones.

-

Bamboo: Lightweight and eco-friendly.

-

-

The wood must be free of knots, cracks, or other defects to ensure a clean finish.

2. Slicing the Wood

-

The selected wood is cut into thin sheets or veneers, typically between 0.5mm to 1mm thick, using precision tools like a bandsaw or laser cutter.

-

The thinness of the wood allows the cards to remain flexible while maintaining strength.

3. Cutting to Size

-

The thin wood sheets are cut into the desired card dimensions. For example:

-

Credit card size: 3.370 x 2.125 inches.

- Business cards: 3.5 x 2 inches.

-

Playing cards: 2.5 x 3.5 inches.

-

-

Cutting is done using a laser cutter or CNC machine for precision and consistency.

4. Sanding and Smoothing

-

The edges and surfaces of the cards are sanded to remove roughness, splinters, or uneven areas.

-

This step ensures the cards are smooth and safe to handle.

5. Design and Customization

-

Designs, text, logos, or artwork are added to the cards using one of the following methods:

-

Laser Engraving: Burns the design into the wood for a permanent, precise finish.

-

Printing: Uses eco-friendly inks to print directly onto the wood surface.

-

Stamping: Creates raised or indented designs on the wood.

-

-

For playing cards, intricate designs (like suits or numbers) are often laser-engraved or printed.

6. Finishing

-

A protective coating is applied to enhance durability and preserve the wood. Common finishes include:

-

Natural Oils: Such as linseed or tung oil, for a rustic look.

-

Varnish or Lacquer: For a glossy, polished finish.

-

Beeswax or Eco-Friendly Sealants: To protect the wood while maintaining a natural feel.

-

-

The finish also helps protect the cards from moisture, scratches, and wear.

7. Quality Control

-

Each card is inspected for defects, such as uneven cuts, scratches, or imperfections in the design.

-

Only cards that meet quality standards are packaged and prepared for distribution.

8. Packaging

-

Wooden cards are often packaged in eco-friendly materials, such as recycled paper, fabric pouches, or wooden boxes, to align with their sustainable appeal.

Tools and Equipment Used:

-

Laser Cutters or CNC Machines: For precise cutting and engraving.

-

Sanding Tools: For smoothing surfaces and edges.

-

Printing or Engraving Equipment: For customization.

-

Protective Coatings: For finishing and durability.

Benefits of Wooden Cards:

-

Eco-Friendly: Made from sustainable, biodegradable materials.

-

Unique: Each card has a distinct wood grain pattern, making it one-of-a-kind.

-

Durable: When properly finished, wooden cards can last for years.

-

Aesthetic: Offers a natural, elegant look that stands out.

Wooden cards are a creative and sustainable alternative to traditional paper or plastic cards, making them popular for businesses, events, and special occasions. Their natural beauty and craftsmanship make them memorable and environmentally friendly.